Offerings

Our Specialisation

Mintech TA is a specialist provider of Hazardous Area Engineering Services and has experience in the inspection, auditing, classification, dossier preparation, design and installation of a wide range of equipment including gas turbine compressors, refineries, dust silos, oil and gas installations, methane extraction, hospital and pharmaceutical facilities and bio-diesel plants, etc.Hazardous Area, auditing by government appointed auditors within Mintech TA, provides a safe environment for those potentially explosive atmospheres.

Our team is committed to ensuring your facility meets Australian compliance requirements and is of the highest safety standard. The hazardous area classification provides a thorough analysis of potential electrical hazards at your site, including flammable mists, vapours and gases, or combustible dusts and fibres.

Working in hazardous areas requires specialist training and expertise. Mintech TA understands the potential hazards that arise where concentrations of flammable gases, vapours or dusts occur. Electrical equipment that is installed in hazardous areas must be specially designed, tested and installed to ensure it does not emit any sparks or flames that could cause an explosion. All work carried out in these areas must comply with Australian standards AS/NZS3000 and AS/NZS60079 and be carried out by a certified Electrical Equipment Hazardous Area electrician. It is a legislated requirement that a pre-energisation audit is performed by a licensed auditor prior to energising new electrical equipment in a hazardous area.

Hazardous areas are those where flammable materials are generated, prepared, processed, handled, stored or used.

Section 221 of the Electrical Safety Regulation 2013 requires that an accredited auditor inspect electrical installations in hazardous areas prior to connection or reconnection to a source of electricity if:

- The installation is being connected for the first time

- Electrical installation work has been performed on an electrical installation within a hazardous area.

This pre-commissioning inspection determines the electrical safety of the installation and that associated electrical equipment such as luminaries have the correct certification and documentation.

MINTECH TA

Auditing service

- Verification dossier and documentation

- Hazardous Area safety systems

- Conformity assessment documentation

- Suitability of the equipment for the area and environment

- Descriptive system documents for intrinsically safe systems

- Details of any relevant calculations; purging rates of instruments and analyser houses, etc.

- Your hazardous area system’s zone classification and required equipment protection levels (EPLs) for the location according to AS/NZS 60079.10.1 and AS/NZS 60079.10.2.

- Inspection/maintenance schedule

- Detailed documentation of maintenance schedule and repairs carried out on equipment plus required intervals of inspection

Hazardous areas site experience

- Power Stations (Coal and Gas)

- Paint Spraying

- Chemical Processing

- Pressurised Control Rooms

- Pharmaceutical

- Oils and Gas drilling and refining

- Oil production storage and offloading

- Refineries

- Distilleries

- Fuel Farms

- Food Manufacturing (dusts)

- Airports & Aviation

- Water Treatment and Sewerage

- Medical (Laboratories)

- Hydrogen Cells

- Fertiliser Plants

HAZARDOUS AREA CLASSIFICATION

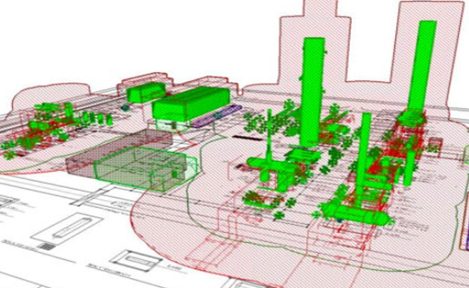

Mintech TA are experts in hazardous area classification procedures for all dust and gas environments.

Adhering to AS/NZS 60079, we will accurately assess and classify areas where flammable gases, vapours, mist or any dust hazards may arise.

“The responsibility for classification of a hazardous area rests with the persons or parties in control of the installation. The requirements are contained within AS/NZS 60079.10.1 for gas and vapour and AS/NZS 60079.10.2 for combustible dusts.” AS/NZS 3000-2018.

Prior to commencing the classification, Mintech TA can assess your installation site and reduce the size of the classified areas by substituting chemicals, implementing control measures and designing ventilation where appropriate. This process can reduce the cost of installation and maintenance and improve safety.

HAZARDOUS AREA DESIGN & INSTALLATION

Mintech TA with our alliance company, Comlek Group Pty Ltd, design hazardous area systems from the ground up, adhering to AS/NZS 60079. We are qualified and equipped to work in all hazardous areas – both gas and dust – spanning a range of environments, including food, pharmaceutical, oil and gas, coal mining, petrol stations and manufacturing.

DANGEROUS GOODS AND HAZARDOUS MATERIALS

Mintech TA offer dangerous goods and hazardous material system design and consultation. Our team can help develop safe systems to store, handle, process and transport your dangerous goods and hazardous materials. Our dangerous goods design team can help with:

- LPG storage and transport system

- Bulk gas storage

- Bunding and material confinement

- Dangerous goods ventilation system design

- Site safe operating procedures

SERVICE & MAINTENANCE

The Mintech TA Team remain up to date with all industry-standard training. Our technicians are equipped with the latest technology and can carry mission-critical spares specific to your operation to ensure that emergency breakdowns and faults can be rectified immediately. Our experience in maintenance projects includes:

- Hazardous area programmed maintenance

- Preventative maintenance of equipment and machinery

- Routine test & tagging

- Exit & emergency testing and repair